How to design a box ?

Design a unique box , make your box clients a happy face

Step 1: Choose the box style you prefer

Magnetic Gift Box( also called book shape style, clamshell box style):

The box style lookes exactly the same as the book shpe box, with the advantage of flat packing. This is the most popular designs among the clients for it can save a lots of space and shipping cost by flat packing. Usually closed by magnet or ribbon. Commonly used for many industries, such as wedding dress gift boxes, fashion shoe box, large beauty gift boxes, etc.

Foldable gift box style:

The box is made with magnet flap, sometimes there is also ribbon included to close the boxes. When you open it, it is just like open a book. That's why some people call it book shape style boxes. The most popular one is the box with magnet closure, like the pink box show below. Some people like the hinged box with elastic band to hold the lid.

Nowadays, the box with ribbon clouse is more and more popular in custom gift box packaging. These boxes are commonly used in apparel packaging boxes, cosmetic packaging box, perfume gift boxes, essential oil box, electronic device packaging boxes, etc.

Gift box with lid style:

This box style contains two parts, lid and bottom carton. But considering different aesthetic standard, there are three models chose by different clients. One model is like the first picture, but lid height is a little large than the bottom so the lid can cover the base. It is normally used for box height less than 5cm.

For box higher than 5cm, we normally make the lid 3cm to save the material cost. That is box with half lid box.

The third one is like the second picture, with shoulder in the middle. Most commonly used in squre boxes. Poplular used in below industries: electronic packaging boxes, wine gift boxes, jewelry gift boxes, cosmetic gift boxes, chocolate gift boxes etc.

Sliding paper box style:

A sliding paper box is ideal for small products. Usually it has a ribbon puller or thumb bottom to open it. A clear PVC is available for you to present the product inside. We can always see the style used for jewelry packaging gift box, electronic products packaging boxes and other small luxury gift box.

Round Tube Box Style:

It is popular used in elegant flower gift box, tea gift box, cosmetic gift box.It is also called hat box for its shape. It is a special shape in base and lid style. So they can also be made with border or not inside.

Corrugated Mailling Box style:

It is made by corrugated box( BE flute, or better KE flute) laminated with CCNB( 250gsm, 300gsm, 350gs).Itis a fashion style for onliner shop owners or companies to ship their products inside domestic or overseas. The most luxury design is too print both inside and outside. But if you want to save cost, you can keep the outside natural brown but inside printed with your logo and company information. In that way, when your clients open the box, they can see your brand easily.

Above box style is only for your reference. We have R&D departments fully supports develop unique packaging style to make your products outstanding among regular.

Step 2: Choose Printing Colors or Specialty Paper

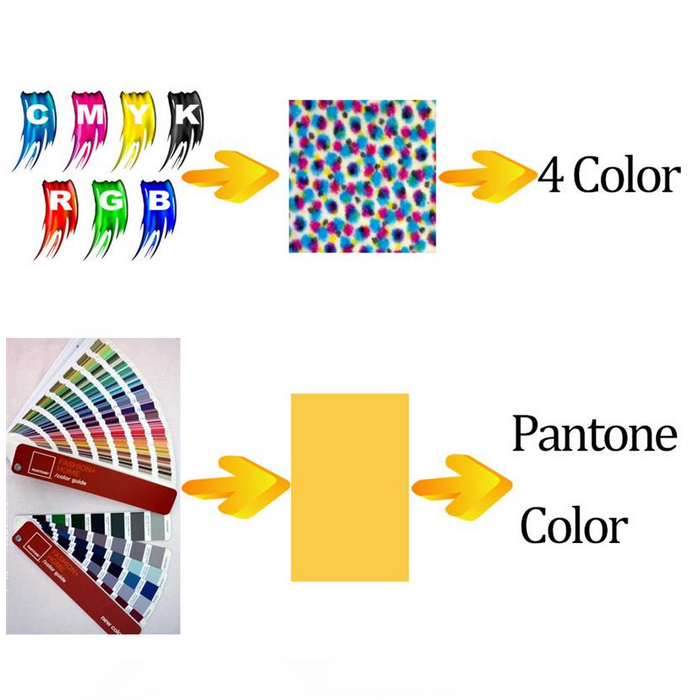

The CMYK model, commonly referred to as "full color printing" or "four color printing". "CMYK" stands for the primary colors of pigment: Cyan, Magenta, Yellow, and Black . CMYK Offset printing is one of the oldest publishing methods that are in use in the present printing enterprise. It allows you to create huge quantities of printed materials at inexpensive prices. A great choice for small and large runs. Despite the affordable price, it produces very high-quality images. Because of its ability to make commercial amounts of prints with the premium quality outcome and inexpensive manufacturing cost, CMYK offset printing is a great option for large quantities of printing projects.

If it is about your logo color, we would suggest you Pantone color printing. It is also call spot color printing.

With the Pantone Matching System (PMS), printers use specific ink combinations to create unique colors for printing. The Pantone system has been in use for several decades, Customizing the box according to the pantone color card number can make your box more colorful than the CMYK box.

What is the difference between using four-color ink, CMYK printing PANTONE spot color, and directly using PANTONE standard spot color ink?

CMYK is overprinted in dots by up to four inks; the use of spot inks is printed by a single ink (solid print, 100% dots). For the above reasons, the former is obviously gray and not bright; the latter is bright and consistent.

Step 3: Choose Surface Finishing

After printing, there are various finishing options available for you to make the surface more special and luxury, like lamiantion, embossing, debossing, spot UV- coating, and all kind of foil hot stamping.

1) LAMINATION

PP Lamination is normally the first step after printing. As it can effectively protect the the printing color from being scratching and also protect the paper from damaging. Except normal glossy and matte lamination, we also provide anti-scratch film lamianation. It looks the same as matte lamination. But the protective effect is much better. It is specially used on black gift box. As on black surface, you can easily left finger mark once touched by hand. But with the anti-scratch film, the finger mark is not easily left on the box surface. Besides, all these lamination can make the gift box water-proof.

3) HOT / FOIL STAMPING

This finish can make your brand metallic looking in different colors. The most popular design is hot stamping in gold or silver color. The cost is calculated based on the area of the stamping part. The larger square meters of stamping, the higher the cost.

4) SPOT UV

UV finishing is a spot glossy finishing, that can make specific design more bright and reflecting. We can make the box with full UV coating, or spot UV coating. But since the price is also calculated by area, it is better to use spot UV to highlight the logo or some important information. But by different factory with different printer, the UV effect can be quite different as below. For experienced factory, the UV finishing should be smooth glossy, but in some factory, you may get the box with bubbles, as you can see by below image.

5) EMBOSSING / DEBOSSED

This finish is used to raise the logo or design so that people can easily see the information that you want to present. Most people like to combine this finshing with hot foil stamping, so that the brand can be not only outstanging but metallic looking. Some unexperienced factory may find it hard to match the embossing part with hot stamping part, but we have solutions to make embossing or debossed finishing is a perfect match on the boxes.

Step 4: Choose the inlay tray

Option 1- Paper insert:

It is the cheapest insert material. Normally made by art paper, kraft paper, gray card,corrugated carton paper etc materials,can die -cutting into any shape and printed with customized pattern, Can be covered with one layer satin fabric be looks more premium, Widely used for chocolate, cake, food, cosmetics, kinds of low & medium value gifts packaging.

Option 2-Plastic blitster insert:

PP,PET,PS,PVC materials,normally in transparent,white,black and gold color,other colors are also available,

Can be flocking or glued one layer customized colorful pattern printed paper on surface to improve the gradeand looks more nice,

With the mold opened based on products shape, it can fully fit in different radian and groove,widely used for electronics, foods, hardware, cosmetics, toys, daily necessities, medicine etc packaging.

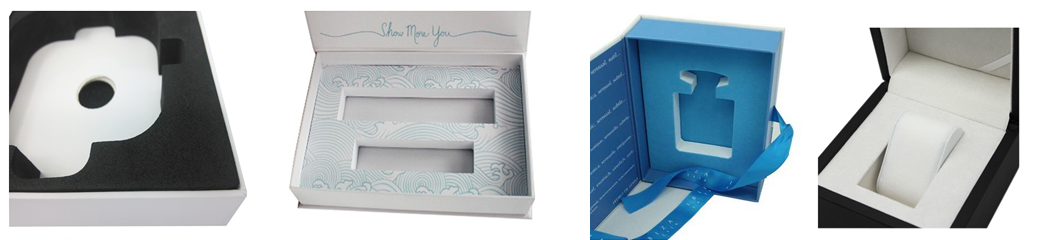

Option 3-Foam insert:

EPS foam(styrofoam,polystyrene foam) or in high-density version,EPE(PE) foam materials,normaly in white color,

With the mold opened based on products shape, it can fully fit in different radian and groove, widely used for pack peach,apple,pitaya,kiwi etc fruits directly or the padded lining of E-commerce express package. For the valued gifts packing like cosmetic, perfume,wine,ceramics,health care products etc it usually covered with one layer satin fabric or flannel/velvet for more luxury.

Option 4- Sponge Insert:

Normal and high-density sponge,in black and white colors,can be use as insert directly,with custom shape die-cutting, also can be loose coverd with satin/silk fabric to looks more fancy, For the jewelry box, it usualy use sponge( in bottom) go with adhesive flanel/velvet/plush(on top) for the insert,

with the cut lines to better fixed the different jewelry.

Option 5-EVA insert:

In diferent grade,usually seen A and B grade(A grade be more pure & solid color,without pore), This material is now the most hard and premium for high-end gifts packaging, can be use as insert directly or glued with one layer custom pattern printed paper or adhesive flannel/velvet,

It suitable for high valued&delicate gifts packaging like perfume, cosmetics, wine bottle, glass artware etc.

Lets Connect with Us

Contact us for the latest product quotes and solutions.

Lishui Town, Nanhai District,

Guangdong Province